Waste Gas Treatment

Domestic projects have been running stably up to standard for 20 years

From Europe and America more than 30 years of mature technology, through the global 2000 cases and domestic more than 300 cases of long-term test

Enduring makes us unique

Our regenerative thermal oxidizer (RTO) is mainly used in the treatment of organic waste gas in different industries such as packaging and printing, coating, spraying and chemical industry, sold more than 2,000 units globally and more than 300 units domestically. Guided by Industry-University-Research cooperation with Jiangnan University, Southeast University and other universities, and appraised by All-China Environment Federation, the scientific and technological achievements of "Key Technologies, Equipment and Application of Low-consumption and High-efficiency Purification of Medium-High-Concentration Organic Waste Gas Project" completed by ATI Group have been evaluated as the international leading level by academicians and experts, selected into the 2021 National Catalogue of Advanced Technologies for Pollution Prevention and Control, and successfully stored in the national scientific and technological achievements database. ATI Group has become a technical support unit for key technologies of low-consumption and high-efficiency purification of medium-high-concentration organic waste gas specified by the Ministry of Ecological Environment, and won the first prize of 2021 Science and Technology Progress Award granted by All-China Environment Federation. At the same time, Wuxi Municipal Ecology and Environment Bureau recommended this advanced technology.

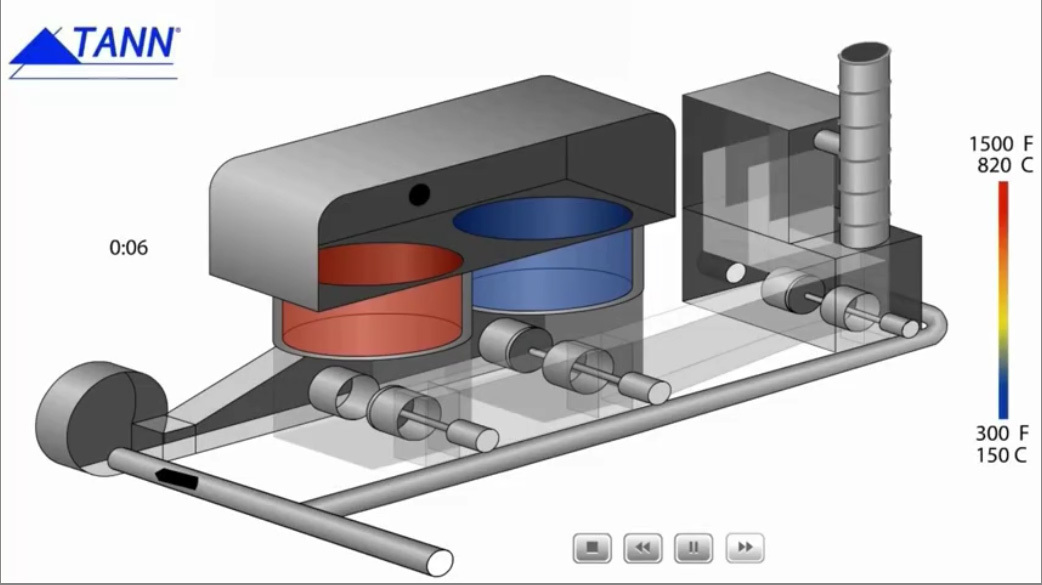

OPERATING PRINCIPLE

Regenerative Thermal Oxidizer (RTO )

Fixed three-chamber purging technology - ATI Group's exclusive patent

INDUSTRY WEAKNESSES

The effect of environmental investment is not ideal, and a second investment is required after a few years

Attenuation of purification rate

· Up to standard in the first year

· Partially up to standard in the second and third years

· Rarely up to standard after four years

Safety hazards

· Flash explosion

· Collapse

High cost of post maintenance

· Natural gas

· Electricity charge

High cost of post maintenance

· High maintenance cost

· Manufacturers out of business

OUR ADVANTAGES

ATI Group's RTO core value - efficient purification

ATI Group applies the steel-to-steel hard-seal poppet valve technology imported from the United States with original packaging, thus achieving long-term treatment efficiency above 99%

Sealing

Steel-to-steel hard sealing technology + high-frequency and high-speed switching

Safety

Five dual systems + over 20 safety interlocks

Energy saving

High efficiency heat storage technology + negative pressure fixed purging technology + waste heat recycling technology

After-sales

24h remote support, fast arrival service

INHERITANCE OF CORE TECHNOLOGY

ATI Group is the exclusive technical partner of the American pioneer RTO inventor - TANN in the Asian market

CLIENT EVALUATION

We will continue to develop with a dedicated attitude and more professional technology to create greater value for customers!

PARTNERS

Witness of Famous Enterprises, Common Choice of More than 100 Partners.

APPLICATIONS

We will continue to develop with a dedicated attitude and more professional technology to create greater value for customers!

01

Printing

02

Building

03

Chemical

04

Coating

05

Spraying

07

Other

CASES

Serve every customer wholeheartedly